The Secrets of Keeping Canned Fruit Nutritious in Vietnam

Nowadays, the canned fruit market is experiencing robust growth, with Vietnam emerging as a key player highly esteemed by the international community. The success of Vietnam in this market is predominantly attributed to its secret in keeping long-term nutrition for the products. In this article, let's delve into the intricacies and quality of this secret in the canned fruit production process in Vietnam, brought to you by WTP Agri.

Purpose of Processing Canned Fruits

A primary objective of the canned fruit process is to preserve them for an extended period, ranging from one to five years, without the use of preservatives while fully retaining the nutritional value of the fruits. Particularly in Vietnam, where surplus fruits during seasons are common, processing and canning fruits prove to be an optimal solution. This not only reduces material waste but also optimally utilizes, contributing significantly to both domestic and export economic efficiency.

Similarly, products derived from aloe vera, canned fruits, not only offer convenience and ease of use for consumers but also provide a nutritional source comparable to fresh fruits, independent of seasonal variations. This not only stimulates fruit consumption in modern society but also creates a flexible and efficient solution to meet the diverse nutritional needs of consumers.

>>> See more: Are aloe vera products healthy?

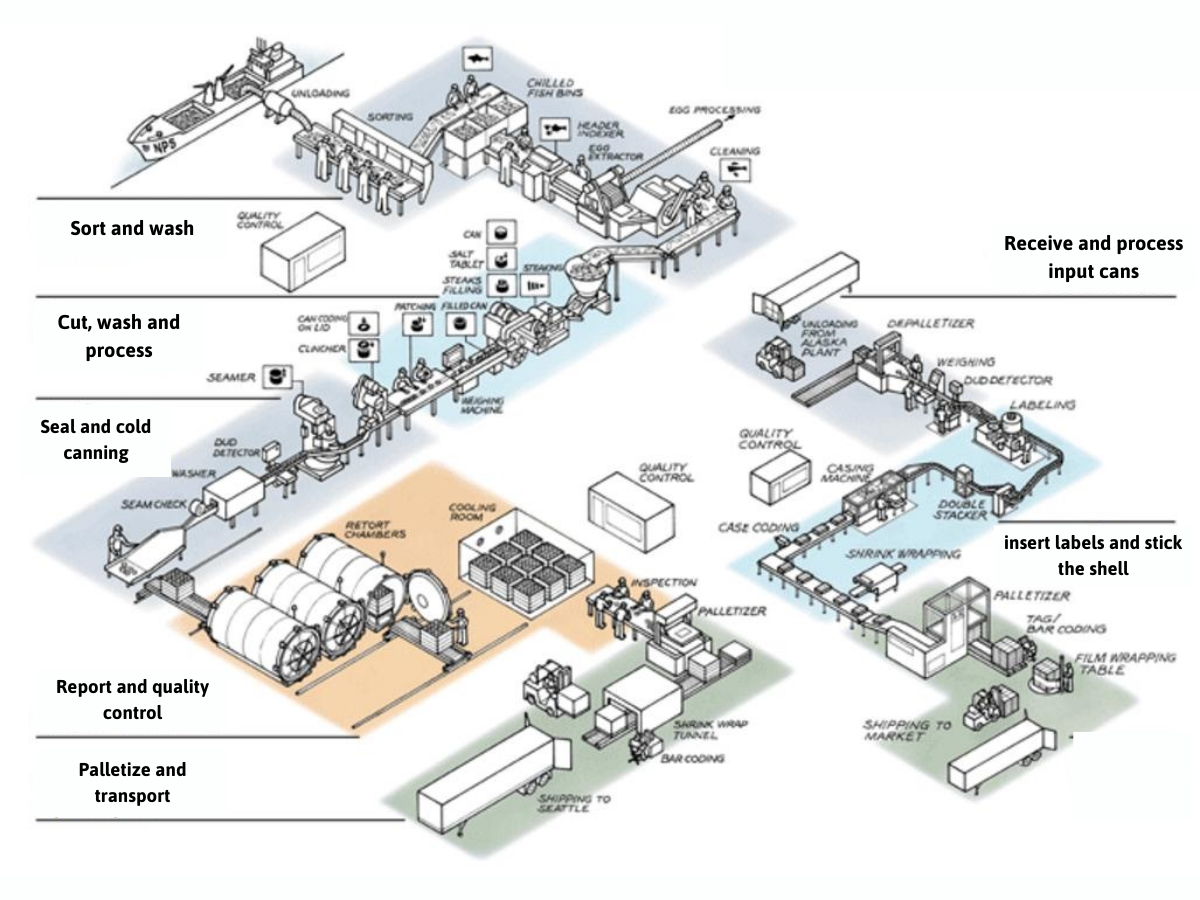

Canned Fruits Production Process

In Vietnam, the production of canned fruits is a seamless integration of modern technology and professional techniques employed by a skilled workforce, resulting in a high-quality end product. The key stages include:

1. Sorting and Cleaning Raw Materials:

Careful selection of ripe, undamaged, bacteria-free fruits free from pesticide residues is imperative for ensuring uniform product quality and facilitating subsequent processing steps. Subsequently, the raw materials undergo a swift, fixed-duration washing process to remove mechanical impurities such as sand and dust, minimizing microbial attachment to the fruit's surface. This washing process is conducted within a brief timeframe to avoid prolonged water exposure. Additionally, the water used complies with Ministry of Health standards quality.

2. Initial Processing (Peeling, Seed Removal, and Dicing):

This stage involves separating the skin and seeds from the fruit, retaining only the high-quality fruit pulp. Subsequently, the product undergoes precision cutting according to the manufacturer's requirements using cutting-edge machinery.

3. Soaking in 0.5% CaCl2 Solution:

To prevent discoloration, this step is carried out immediately after the initial processing. Its objective is to enhance the fruit's firmness, improving its aesthetic appeal while simultaneously eliminating surface dust and adhesions.

4. Heat Treatment of Raw Materials:

Fruits are preheated by steaming at a temperature of 80–100°C for 3–15 minutes depending on the type, then immediately cooled to ensure product quality. This stage helps deglaze and remove air from the ingredients, prevents swelling and improves the taste of the product by removing unwanted odors from the ingredients.

5. Packing into Cans:

Before packing, the cans undergo cleaning with a 1-5% diluted alkaline solution, followed by a rinse with clean water and thorough drying. To ensure cleanliness, the product is placed into the cans on stainless steel tables. When loaded into the can, the product must fill the can's net weight capacity, occupying approximately 55-80% of the net weight.

6. Cooking and Pouring Sugar Syrup Solution

The solution, consisting of sucrose and citric acid in water, is heated to 95°C within a continuously stirring cooking apparatus. When pouring the solution into the pre-stacked cans, the sugar water should be at a temperature of 80-85°C, and it is advisable to pour with a margin of 7-10mm from the can's rim. To prevent lid popping during sterilization, caution should be taken not to overfill. Following the sterilization and cooling process, the weight of the fruit content within the can is expected to decrease by approximately 5-10% compared to its pre-canning state.

7. Deaerating and Lid Sealing

Following preservation, the products undergo a deaerating process to remove excess air from the cans before sealing, preventing issues like bulging or lid wrinkling during sterilization. Subsequently, the lids are sealed using a vacuum level of 300-350mmHg. Alternatively, lid sealing can be performed immediately after deaerating at a temperature of 85-90°C for approximately 10-15 minutes. Swift execution at this stage is crucial to avoid discoloration and the risk of product contamination.

After this step, we proceed to the next stage within 30 minutes to prevent fermentation and reduce the initial temperature of the can, helping to ensure a coherent and high-quality production process.

8. Sterilization

The sterilization system maintains a temperature of 980°C for a duration ranging from 10-25 minutes. Post-sterilization, cooling is a critical step to preserve the flavor, color, and firmness of the canned product, while also reducing the risk of corrosion to the iron can. This cooling process not only lowers the temperature but also aids in eliminating residual microorganisms and enzymes, enhancing the product's shelf life and maintaining its quality.

9. Insulation Process

After cooling, the cans are thoroughly cleaned, dried, and transferred to the finished goods warehouse. Here, the products are palletized for insulation for 7-15 days, undergoing quality checks to ensure adherence to production standards.

10. Preservation

Following the insulation phase, the products are cleaned and coated with oil to protect the cans from rusting. Prolonged preservation must be carefully executed to prevent alterations in quality, such as diminished flavor, color changes and decreased vitamin levels. To ensure quality, the products are stored in a dry, clean, and well-ventilated warehouse, with rules like placing canned goods upright, stacking them in blocks, and not placing them directly on the warehouse floor. Safe distances from ceilings and walls are also specified to ensure optimal storage conditions.

11. Labeling and Packaging

Finally, the canned fruits are labeled using specialized labeling machines, ensuring complete coverage and accurate content information on the can's surface. After thorough inspection, the cans are stacked in boxes according to specifications and prepared for transportation.

Vietnam possesses significant potential to become a leading exporter of canned fruits, thanks to abundant raw materials and the use of modern machinery in the production process. This results in high-quality products that meet stringent international standards. WTP Agri, a reputable canned fruit supplier in Vietnam, operates a state-of-the-art facility, compliant with international standards such as IFS, BRC FOOD, HALAL, and FSSC 22000. We stand ready to be a reliable partner on your journey to conquer the canned fruit market.

Do not hesitate to reach out to us for further insight and exploration into how we may contribute to the sustainable development of your enterprise. Contact us by filling out the contact form which you can find on this page. Either get in touch with our team at agri.crm@wtp.vn or give us a call on (+84)971 279 099. And remember we can also provide tailored service if you need it.

News Related

- Dried Fruits Import: Attractive Business Opportunity for International Businesses

- 5 delicious and refreshing nata de coco drink recipes

- A step forward in bilateral cooperation between Vietnam - the United States

- Advantages of shifting the fruit juice supply chain to Vietnam

- Aloe Vera Juice – Manufacturer and Supplier

Vietnamese

Vietnamese  Korean

Korean Japanese

Japanese Chinese

Chinese